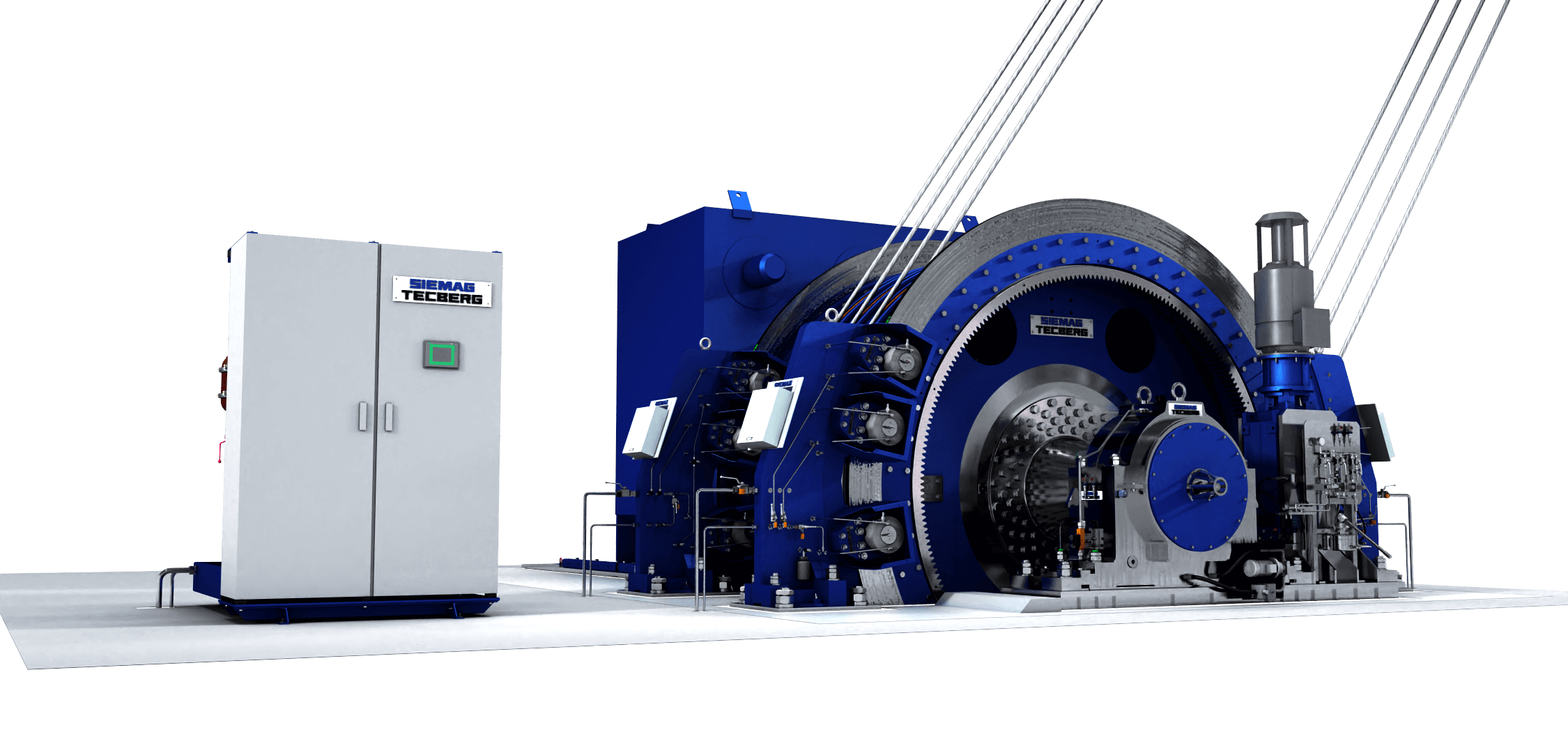

Ross shaft main hoisting system modernized

2 Nordberg drum machines from 1934 modernized by SIEMAG TECBERG Inc.

Customer

Sanford Underground Research Facility (SURF), South Dakota

Country

USA

The Sanford Underground Research Facility (SURF) hosts world-leading research experiments in physics, biology, geology and engineering. The South Dakota Science and Technology Authority (SDSTA) manages the Sanford Underground Research Facility. The Sanford Underground Research Facility (SURF) advances world-class science and inspires learning across generations. We support active research in particle and nuclear physics and other science disciplines. While still a gold mine, the facility hosted Ray Davis's solar neutrino experiment, which shared the 2002 Nobel Prize in Physics. His work is a model for other experiments looking to understand the nature of the universe. The facility's depth, rock stability and history make it ideal for sensitive experiments that need to escape cosmic rays. The impacts on science can be seen worldwide.

Year of commissioning

2022

Material to be conveyed

Debris / Rock

Services within the scope of the project

- Conversion of the direct-current drives to alternating current. The existing motor-generator components were removed and new frequency inverters and new drives installed

- The clutch of the underwound drum was fixed/taken out of operation

- The clutch of the overwound drum was replaced with a clutch with a ring gear

- Brake systems were fitted with a new control systems

- For the operation of the old low-pressure system electric linear drives and new hydraulic valves were used to provide additional levels of safety

- Operator control is now by means of touch screen and joystick in a control station

- Conversion of the direct-current drives to alternating current. The existing motor-generator components were removed and new frequency inverters and new drives installed

- The clutch of the underwound drum was fixed/taken out of operation

- The clutch of the overwound drum was replaced with a clutch with a ring gear

- Fitting of the winding machine with gearbox brake

- Old brakes were replaced with new brakes with disk springs

- All the old low-pressure coupling and brake hydraulic systems were replaced with a new high-pressure system

- Operator control is now by means of touch screen and joystick in a control station

Information about the project

In January 2021 the 2 Nordberg-type drum winding machines of the Ross shaft were shut down for purposes of modernization. These machines comprise, on the one hand, a 2 drum winding machine for production with a skip on each drum and, on the other hand, a 2 drum winding machine for personnel and materials with a cage on one drum and a counterweight on the other. Both winding machines were designed in 1933 and installed in 1934.

To achieve the efficient excavation of more than 700,000 t of rock and safe personal transport the two Nordberg winding machines had to be fundamentally modernised. The US subsidiary of the shaft hoisting technology specialist SIEMAG TECBERG was awarded this contract not only because of its competence in the modernisation of shaft hoisting technology but also because of its special knowledge of Nordberg winding machines: in 1999 the mining arm of the American Nordberg Manufacturing Company was taken over by SIEMAG US Inc, a predecessor corporation of SIEMAG TECBERG.