Shaft and Heavy-Duty Hoisting Systems for the Polyhalit project in North Yorkshire

8 hoisting machines and 16 stage winches for Woodsmith Mine

Customer

Anglo American

Country

England

Anglo American is a global group involved in mining and processing of raw materials. The company, which is listed on the stock exchange in London and Johannesburg, is headquartered in London. The company employs around 105,760 people and generates annual sales of around $35 billion. The mining sector is Anglo American's core business, ahead of metal refining.

Year of commissioning

2021

Purpose of the heavy duty equipment

Support or enable sinking operations for the production / service shaft (1600 m), as well as sinking operations for the two shafts of the material handling system (370 m).

Information about the project

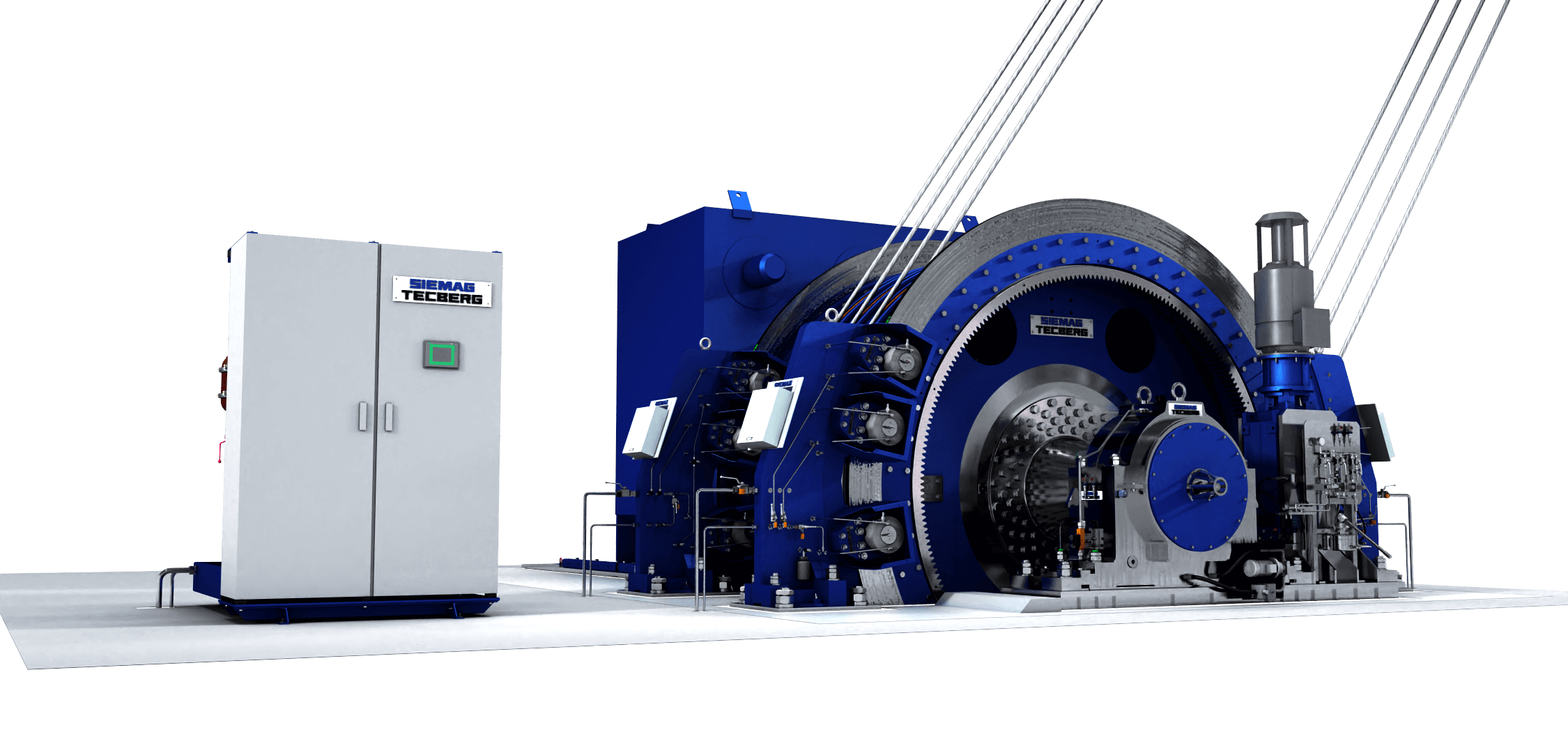

In September 2018, SIEMAG TECBERG group received a major order for the supply of a total of 8 hoisting machines and 16 stage winches for use in several shafts with depths of 1,600 m and 370 m for the new Woodsmith mine and Lockwood Beck shaft in the North York Moors National Park in the northeast of England. The North Yorkshire Polyhalite Project is one of Europe's largest underground mining projects. The world's largest polyhalite deposit, located beneath a national park, is accessed via a 37km access tunnel for nature conservation reasons.

The order included the planning, manufacture and delivery of hoisting systems, including the associated automation and drive equipment, braking systems to the highest safety standards and supervisory monitoring system for the hoisting equipment installed in and on the shaft. In the interim, the scope of delivery has been extended by 53 rope sheaves and additional equipment for automation technology stemming from the supplier.

Shaft hoisting equipment for the production and service shaft (diameter 6.75 m)

Eight stage winches were included in the scope of delivery. With a total of four absolutely synchronously operated stage winches, the Herrenknecht shaft boring machine SBR (Shaft Boring Roadheader) weighing approx. 368 t is held or moved in the shaft during the sinking operations. Two synchronously operated stage winches were supplied to support the shaft development and to install the shaft fixtures. A sinking hoist unit is to be supplied for trasnporting personnel in the rope-guided kibble, mucking operations and material transport.

Shaft hoisting equipment for the shafts of the material transport system (diameter 8 m)

SIEMAG TECBERG group provided all hoisting machines, stage winches and rope sheaves necessary for sinking the MTS shafts and for the subsequent tunneling phase involving mucking operation and material transport. This included four stage wiches, two double-drum hoisting systems, two single-drum heavy duty hoisting machines and two single-drum hoisting machines as permanent auxiliary hoists.

Further information